Fully Integrated Bird's Nest Producer: 100% Pure and Natural

SunshineNest® is a fully-integrated bird’s nest producer - from the construction, maintenance and harvesting of our own swiftlet farms right through to the processing of the nests as well as packaging, sales and distribution. As we are in control of the whole process, we can assure you that our bird’s nests are 100% pure. Throughout the entire production process, no chemicals, additives, preservatives or colourings are used to ensure that all of the natural goodness of bird’s nest is preserved. In addition, as the precious nutrients in bird’s nests can be easily destroyed by high temperatures from heating ovens, our bird’s nests are dried using low-temperature drying methods in specially-designed rooms. As a result, SunshineNest® bird’s nest still retain its ability to expand at least 7 times after soaking, a key distinguishing feature of authenticity for bird’s nests.

Click here to see a step-by-step overview of our production process.

Low Moisture Content

Another distinguishing feature of our product is its low moisture content. Most bird’s nests sold in the market would already be prepackaged in boxes so the consumer would not know how much moisture the bird’s nest contains. As bird’s nest can absorb water up to 10 times its own weight, unscrupulous traders intentionally spray the bird’s nests with water to make the nests heavier and thus sell for more. Excessive moisture in the nests also encourages the growth of fungus or mould. At SunshineNest® we believe in giving our customers the best quality bird’s nest by ensuring that maximum dryness is achieved for each piece of bird’s nest, meaning more bird’s nest and less water in every gram!

Individual Packaging : Hygienic and Convenient Food

Each piece of SunshineNest® bird’s nest is individually packed in protective food-grade film, providing a convenient yet hygienic way to handle and store these delicate gifts of nature. This individual packaging also offers our customers the unique opportunity to pick and choose each and every piece of bird's nests to their liking, as well as the chance to feel for themselves the very low moisture content of our bird's nest.

Food Safety & Quality Compliance

Our commitment to producing high quality bird’s nest is second to none. To ensure we meet the highest food safety and quality standards, our bird’s nest products are sent for microbiological, chemical and nutritional tests and analysis on a regular basis. In 2011, SunshineNest® proudly became one of the first raw bird’s nest producers to achieve VHM (Veterinary Health Mark) accreditation from the Department of Veterinary Services Malaysia, certifying that our processing methods and facilities fulfil the requirements to produce clean and pure bird’s nests in accordance with internationally-recognised HACCP (Hazard Analysis and Critical Control Points) and GMP (Good Manufacturing Practice) programmes. Since then, our pursuit for excellence has continued with Halal certification (May 2012) and HACCP certification (Aug 2012)

Controlled, Hygienic Farm

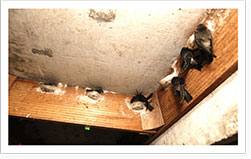

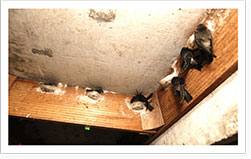

SunshineNest® focuses on producing “house” bird’s nests from white-nest swiftlets only, as the controlled and hygienic environment provided in swiftlet farms produces cleaner nests. Studies have shown that “cave” nests and “house” nests are equally nutritious.

However, “cave” nests have a much higher chance of containing other impurities due to the external environmental surroundings. Also, a significant amount of “cave” nests are of the black nest swiftlet variety, which inherently contains at least 3 to 4 times more feathers. As such, to save processing time, “cave“ nests are more likely to have been bleached or artificially treated to whiten the nests and camouflage the small feathers.

SunshineNest® is a fully-integrated bird’s nest producer - from the construction, maintenance and harvesting of our own swiftlet farms right through to the processing of the nests as well as packaging, sales and distribution. As we are in control of the whole process, we can assure you that our bird’s nests are 100% pure. Throughout the entire production process, no chemicals, additives, preservatives or colourings are used to ensure that all of the natural goodness of bird’s nest is preserved. In addition, as the precious nutrients in bird’s nests can be easily destroyed by high temperatures from heating ovens, our bird’s nests are dried using low-temperature drying methods in specially-designed rooms. As a result, SunshineNest® bird’s nest still retain its ability to expand at least 7 times after soaking, a key distinguishing feature of authenticity for bird’s nests.

Click here to see a step-by-step overview of our production process.

Low Moisture Content

Another distinguishing feature of our product is its low moisture content. Most bird’s nests sold in the market would already be prepackaged in boxes so the consumer would not know how much moisture the bird’s nest contains. As bird’s nest can absorb water up to 10 times its own weight, unscrupulous traders intentionally spray the bird’s nests with water to make the nests heavier and thus sell for more. Excessive moisture in the nests also encourages the growth of fungus or mould. At SunshineNest® we believe in giving our customers the best quality bird’s nest by ensuring that maximum dryness is achieved for each piece of bird’s nest, meaning more bird’s nest and less water in every gram!

Individual Packaging : Hygienic and Convenient Food

Each piece of SunshineNest® bird’s nest is individually packed in protective food-grade film, providing a convenient yet hygienic way to handle and store these delicate gifts of nature. This individual packaging also offers our customers the unique opportunity to pick and choose each and every piece of bird's nests to their liking, as well as the chance to feel for themselves the very low moisture content of our bird's nest.

Food Safety & Quality Compliance

Our commitment to producing high quality bird’s nest is second to none. To ensure we meet the highest food safety and quality standards, our bird’s nest products are sent for microbiological, chemical and nutritional tests and analysis on a regular basis. In 2011, SunshineNest® proudly became one of the first raw bird’s nest producers to achieve VHM (Veterinary Health Mark) accreditation from the Department of Veterinary Services Malaysia, certifying that our processing methods and facilities fulfil the requirements to produce clean and pure bird’s nests in accordance with internationally-recognised HACCP (Hazard Analysis and Critical Control Points) and GMP (Good Manufacturing Practice) programmes. Since then, our pursuit for excellence has continued with Halal certification (May 2012) and HACCP certification (Aug 2012)

Controlled, Hygienic Farm

SunshineNest® focuses on producing “house” bird’s nests from white-nest swiftlets only, as the controlled and hygienic environment provided in swiftlet farms produces cleaner nests. Studies have shown that “cave” nests and “house” nests are equally nutritious.

However, “cave” nests have a much higher chance of containing other impurities due to the external environmental surroundings. Also, a significant amount of “cave” nests are of the black nest swiftlet variety, which inherently contains at least 3 to 4 times more feathers. As such, to save processing time, “cave“ nests are more likely to have been bleached or artificially treated to whiten the nests and camouflage the small feathers.

Related